Printed wiring boards are not the latest addition to tech reality. But the power of adaptation and evaluation made the printed circuit boards or PCBs one of the must-have ingredients in the electrical engineering era. These designed boards are usually made up of simple holes and vias with imprinted designs and patterns. But what makes the PCBs unique is the layering and flexibility. The more layers you add, the better dimensions you see. The fundamental rules may look as simple as they are. But with every layer, there adds some possibility of efficiency and error. This article will get to know what you need to check out before ordering your PCB manufacturers. Please scroll below for the insight.

Things Before Ordering

Do your homework before ordering the manufacturers of what you truly need. To do that, at first, get a vivid idea about the parts and their importance. Decide the PCB size. The size depends on the enclosure and product compatibility and efficiency. Then be sure of the layering. Usually, there are single-layered, bilayered, and multi-layered PCB boards. Multi-layered boards are famous nowadays for making compact devices. Two layers are used to make simple, instruction following toys, and three layers are for home appliances and such. More than or six layers are used to make the smartphone or better gadgets. If you can be sure of your requirements, you may save money on the fpc materials and avoid extra touch-ups and less consultation fee.

Manufacturers Guide

If you are a PCB board manufacturer, then the responsibility on you is enormous. Developing every single part accurately, PCB fabrication, and assembling, too, beating the deadline is not easy. So, to finish the mammoth task, take the notes first and start accordingly from the very beginning. Clear out the core material the clients need. There are codes of core materials like FR4 for the fiberglass or epoxy derivatives core. FR3 is for the cotton paper base, and FR2 goes for the phenolic derivatives. The fiberglass core is the most adjustable and thermo resistant material for a PCB. But it’s also pretty expensive. You can consult the patients to choose, keeping the long-run effects in mind.

Be sure about the layering, thickness, and surface marking, and colorings. The usual thickness of a PCB board is about 0.5 to 1.00 mm. If the party needs more layering in the least possible thickness, then the accuracy and machine you will need are more expensive. Make it clear to the client during the consultation period because keeping clean in business matters. Surface finishing is an essential issue for clients. As this part will be visible at first, someone opens the hood of any machine or gadget. The best surface finishing chemical is electroless Nickel or immersion gold: direct immersion gold (DIG), Organic solderability preservatives( OSP), and such. The copper board weight is usually 70um or 18um. The thinner the copper board, the more compact the design will be.

Fabrication

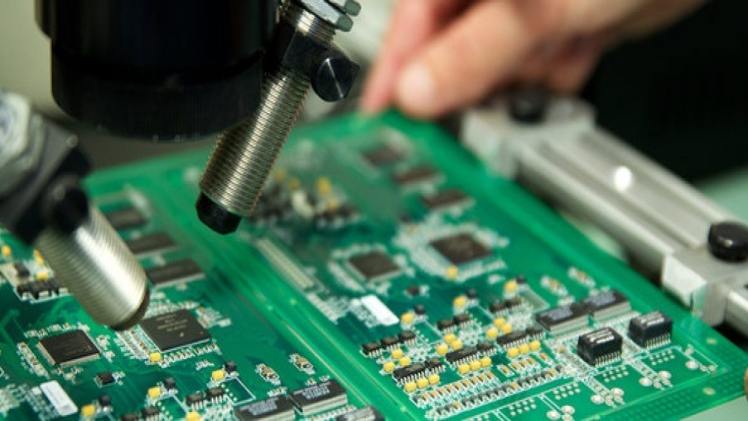

After you print out the PCB copper board layout and fix every hole and vias with proper heat seal and compression, check for the wrapping effect. If there is any unwanted spark or improper connection, then make it right again by reversing the developmental process. PCB fabrication is like leaving the tricycle behind and going full-on yourself. PCB Fabrication makes a design ready for the consumer’s use.

Conclusion

Make sure your materials type number does not exceed the manufacturer’s SMT machine support. Otherwise, they won’t be able to produce the correct line. Work to optimize and redesign every time you try to make a new lot of PCB.